Compression Springs 12 Compression Spring Design Definitions 13 Compression Springs - Other Configurations 14 Pressed Strip Springs 15 Wave Spring Washers 16 Wire Forms 16 Standard Wire Gauges 18 Conversion Tables 20 Manufacture 22 Terminology 24 Notes 29. Principles of Construction.

Whether single or twin brush springs are required motor brush springs are the ideal method of ensuring consistent dependable.

. From inside the book. Minimum load is the amount of force required to start to extend. Do not use to hold overhead loads.

History of the material Natural rubber is chemically cis 14 poly- isoprene and occurs naturally as latex which is a colloidal suspension in the juice of a number of plants. Stress evaluation of conical rubber spring system R. Rubber springs design by Ernst Friedrich Göbel.

Excess rubber material left on a rubber part or component after molding. A short guide to the design of rubber springs is given and the use of rubber in railpads bridge bearings and vehicle suspension units is described as a series of examples. If you are designing a potable water application consider the use of an EP rubber as long as the rubber.

We havent found any reviews in the usual places. The forms of energy are. The helical springs are made from a wire coiled in the form of a helix as shown in Figure 1.

For technical design or application assistance call toll free. Design development and application of a compression type 100 rubber spring has proved to be very successful on single and tandem axle suspensions for trucks and trailers. 7664191 in Books See Top 100 in Books 232345 in Engineering Books Brief content visible double tap to read full content.

Up to 24 cash back Design of various types of springs optimization of helical springs -- rubber springs -- Design of flywheels considering stresses in rims and arms for engines and punching machines. Design springs with high precision. These fabric-covered rubber springs stretch up to three times their original length much farther than traditional extension springs tie downs and shock cords.

For the simulation purpose the adopted design of the basic metal rubber spring element was Fig. Nitrile rubber is a good general purpose rubber. Among the objectives of the rubber spring were a free height not to exceed 8 in static capacity of approximately 20000 lb a load deflection of.

What people are saying - Write a review. Design and optimization of rubber metal springs Constructor defines the initial geometry of the element based on the project task. The parameterized nonlinear finite-element model of the rubber spring which used as the main elastic component in a construction vehicle suspension has been built in this paper.

Examples of Applications. Whether single or twin brush springs are required motor brush springs are the ideal method of ensuring consistent dependable. After this step the initial geometry is being optimized.

The non-linear stiffness curve of vertical direction was obtained by FEA which accord with the experiment results very well. The physical and chemical structures of rubber are described. The smooth rolling action of Contorque springs is ideal for cable extensions and provides an alternative to battery motors or dead weights.

Cross-section of the wire is generally circular and it can be square or rectangular also. These are suitable for many industrial applications and are readily available. The use of conventional steel as spring material increases the overall weight of the automobile suspension system and hence the.

Rubber springs design This edition was published in 1974 by Wiley in New York. Design Contorque springs allow numerous turns without a change in force. Our expertise allows us to assist customers in creating cost effective solutions.

UNIT V DESIGN OF BEARINGS AND MISCELLANEOUS ELEMENTS 9 Sliding contact and rolling contact bearings -- Design of hydrodynamic journal bearings. The sensitivity analysis of structural. 1-800-BARRY MA Dimensions Load Range Data Elastomer Spring Series Barry Controls 40 Guest Street Brighton MA 02135-9105 617 787-1555 Fax 617 787-7807 A L B Part Number ES-3500 ES-3501 ES-3502 ES-3503 A63 B25 1532 58 2532 1 L 436 353 292.

This edition doesnt have a description yet. Full content visible double tap to read brief content. They determine the stress-strain viscoelastic and fatigue properties and the effect of the environment which in turn control the use of the material in engineering applications.

View 4 Editions Details. All have carabiner ends with spring-loaded latch openings. Item Weight.

Then British Asian colonies using rubber trees from seeds smuggled out of the Amazon basin began to. South America particularly Brazil was the prime source of natural rubber until the early 1900s. A short guide to the design of rubber springs is given and the use of rubber in railpads bridge.

Abstract This project focuses on the design development evaluation and analysis of an adjustable vehicle suspension system. A rubber sample in a compressed state at true transformed. Can you add one.

Robert has tried treplace the metal coil spring of a Rover saloon car using carbon fiber. Mortel Department of Product Design Trelleborg-Industrial A VS UK Abstract The conical rubber springs manufactured by Trelleborg-Industrial AVS is a primary suspension layout used between the bogie frame and the axle box for railway vehicles. Helical springs are easy to manufacture reliable and have a constant spring rate ie spring deflection is directly proportional to the.

Minnesota Rubber materials 366Y a 70 Shore A nitrile rubber or 514AD a 70 Shore A fluoroelastomer rubber. As you stretch an extension spring it gets harder to pull. Flooring electrical insulators springs and pneumatic tyres.

Can be removed by tear trimming cryogenic deflashing tumbling and other post molding operations. Spring Engineers of Houston is highly experienced in the design of many types of springs for many different industries. And rubber core unidirectional laminate with a braided outer layer.

Flash is the result of the rubber material or compound migrating through the mold surface finish and mating surfaces. As the number of applications increased demand for the raw material grew rapidly. Wiley 1974 - Rubber goods - 211 pages.

Figure 171 Helical Spring. Spring design is challenging because of the conflicting priorities in a given application. Springs are energy management devices.

This system is aimed to improve vehicle performance on all terrain. 0 Ratings 3 Want to read.

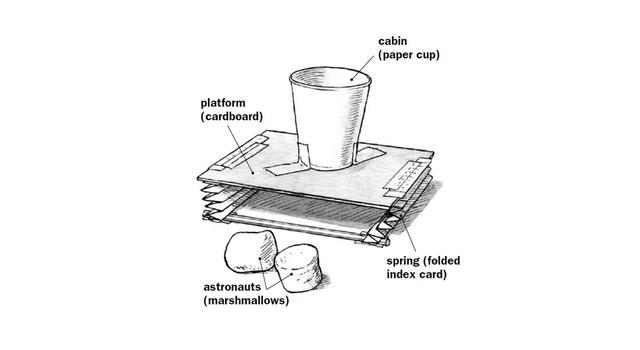

Educator Guide Touchdown Nasa Jpl Edu

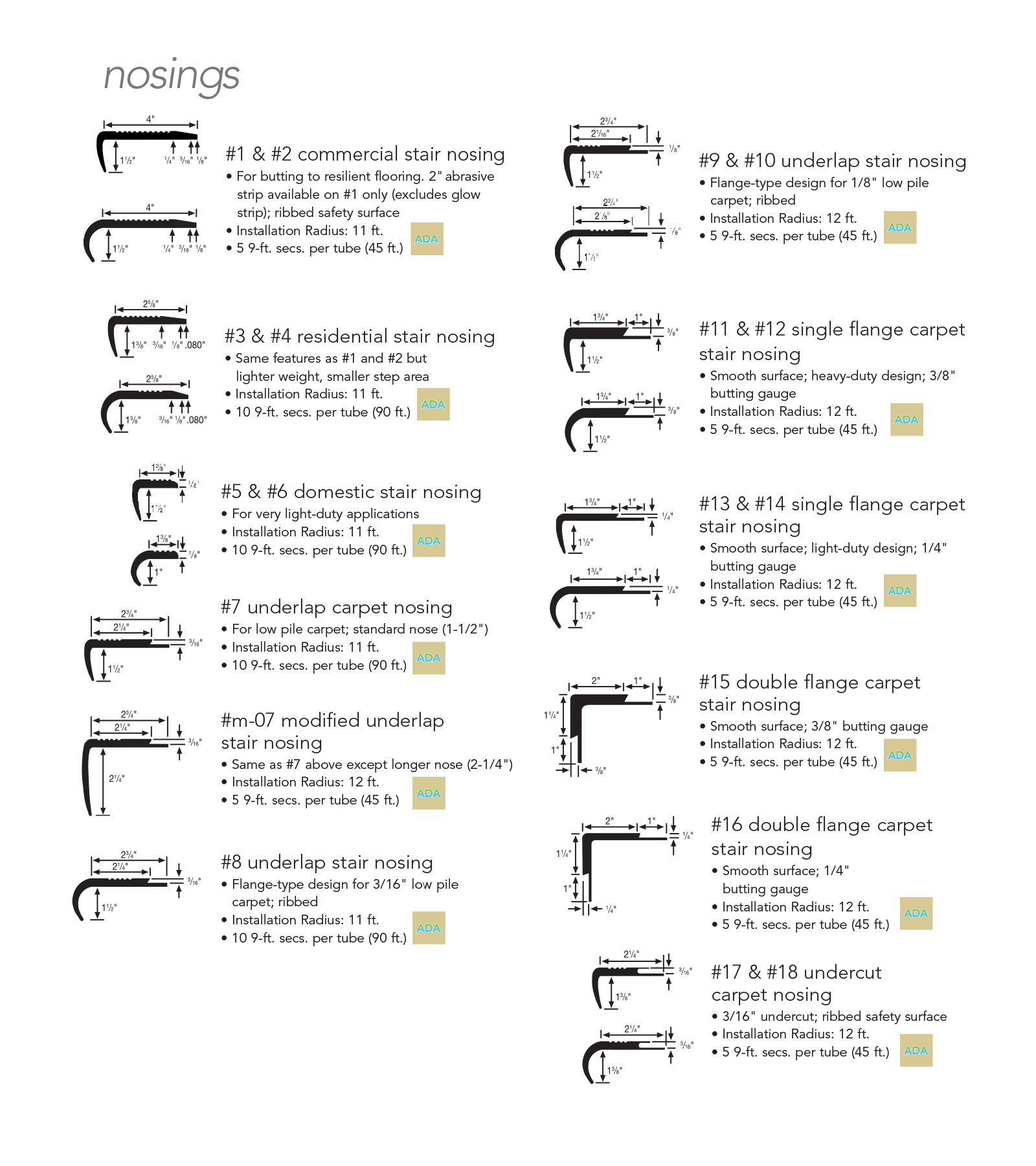

3d And 2d Cad Files For Casters Easy Access Caster Connection

0 comments

Post a Comment